Indicators on Bricklayer Auckland You Should Know

Wiki Article

Some Ideas on Bricklayer Auckland You Should Know

Table of ContentsThe Ultimate Guide To Bricklayer Auckland9 Simple Techniques For Bricklayer AucklandThe Definitive Guide to Bricklayer AucklandMore About Bricklayer Auckland

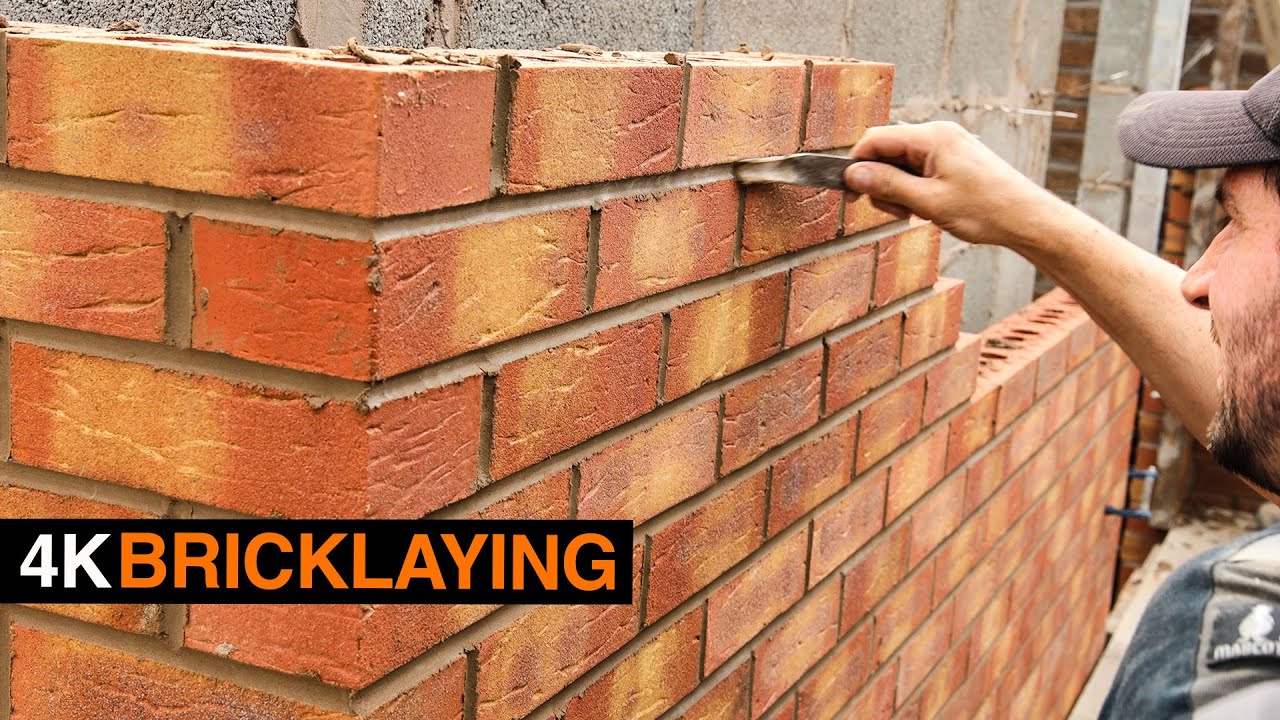

The difference between ZERO as well as classic stonework is in the laying of the block. The block is no more pressed up and down, but slanted. No has a special opening on the upper side of the block. Consequently the mortar bed is lower. It will certainly sink even deeper when the next training course of blocks is laid.In addition, we additionally paid interest to an excellent proportion in between the size as well as size of the block so that it is excellent for working with a cot bond. Bricklayers are an important career in the building sector, accountable for laying blocks, pre-cut rock and also concrete blocks in mortar. Bricklayers construct, expand and repair residential and business buildings, as well as various other structures such as foundations, walls, smokeshafts or ornamental stonework.

Your time as a bricklaying pupil will normally be split between your company and also training company (such as a college), with at the very least 20% of your typical functioning hours invested in training. Your training might happen weekly, every month or in a separate block of time, and it can take location at your area of work, at your training supplier or online.

The smart Trick of Bricklayer Auckland That Nobody is Talking About

When researching building and construction, you invariably find that any type of new or cutting-edge suggestion has really been tried over as well as over again, often extending back decades. Among these new-but-actually-old suggestions is the idea of a mechanical bricklayer, a device to automate the construction of masonry wall surfaces. It's simple to see the allure of this idea - stonework building and construction appears virtually completely matched for mechanization.It doesn't look like it would certainly call for literally complex motions - each brick obtains a layer of mortar applied, and also is just laid in place following to the previous one. And since each physical joint is the same size, positioning is virtually deterministic - each block is the very same fixed range from the previous one.

These makers couldn't notice anything concerning their setting, or measure where a block required to go - they merely squeezed out a layer of mortar and also mechanically put a block at regular periods (Bricklayer Auckland). It's uncertain the amount of of these makers ever made it past the drawing board, but at the very least one of these (John Knight's) was made use of to develop a brick wall surface that presumably still stands today.

Over the years, masonry has declined in special info relevance as a building innovation in the industrialized world, as well as with it the passion in automating it. Unlike with concrete 3D printing, where there are loads of efforts to develop the innovation, I can only locate a handful of current initiatives to automate masonry. Bricklayer Auckland.

All About Bricklayer Auckland

It can placing blocks in tight corridors or complicated edges, as well as Hadrian can build all the walls of a small building with just a few moves of the lorry. Hadrian can currently set about 200 obstructs an hour, yet they're aiming to be able to do 1000 blocks a hr or even more (the blocks it sets are various from the block stonework made use of in the United States, but in US masons can set someplace in the area of 400 obstructs a day).

SAM has a collection of sensing units to make up for the motion of the platform and ensure it's placing blocks degree, and can work with blocks of all different dimensions (though it will not construct CMU block wall surfaces). It obtains placed to a movable scaffolding that's elevated gradually as the wall is completed.

The promotional material on Construction Robotics' internet site recommends that it's no longer their main emphasis - more focus is provided to their other product, MULE.Other than SAM as well as Hadrian, there are a couple of various other mechanical bricklayers in numerous phases of growth. You likewise see the occasional scholastic effort. One area where we do see some business success with mechanical bricklaying is with brick roadways - a range of business provide makers that can "print" an area of roadway made of bricks.

The Ultimate Guide To Bricklayer Auckland

A somewhat different group of machines intended at improving stonework efficiency is what I'll call "masonry aides". These are machines designed to help with physically lifting the block (they appear to be a lot more usual with block than brick) as well as taking the stress off why not look here the mason, while still allowing the mason to adjust it into position, Stonework aides day from a minimum of 1994, when the military explored with MOM, the Mechatronically Assisted Mason's Help.

Report this wiki page